As vehicle and industrial systems become more compact and complex, many gasket applications require both structural support and reliable sealing performance. That’s where overmolding comes in.

Read MoreView our gallery of self-lubricating seals and learn why self-lube material can help save money and time in the automotive manufacturing process.

Read MorePremium Seals - our focused factory for electrical connector seals - is featured in this month’s Rubber News. Click here to read the full article.

Read MoreEvery gasket and seal we manufacture in Mexico benefits from a series of specialized processes before and after molding. This video offers a glimpse into several of these critical capabilities.

Read MoreFounded in 2005 by Kevin Morgan (CEO) and Alex Borboa (GM), Premium Seals was established as a dedicated manufacturing partner for electrical connector programs and serves as a strategic extension of Morgan Polymer Seals.

Read MoreM.A.G.I.C. is a proprietary vision inspection technology designed and built by our expert engineers to provide total and repeatable accuracy during the inspection process.

Read MoreEach year, we ship nearly 100 million precision-molded parts to OEMs around the world, and our commitment to excellence has earned us recognition from partners such as Ford and GM, who have honored us with 100% on-time delivery ratings year after year.

Read MoreInjection molding is one of the most reliable methods for creating durable, consistent gaskets and seals for our automotive OEMs around the world.

Read MoreCongratulations to our Quality Engineer, Ana Paulina Galaz, featured in this year’s class of Rubber News “Women Breaking The Mold”.

Read MoreWhat makes wasteless transfer molding a specialized process?

Read MoreThis gallery shows off some of our gaskets and seals molded with Hydrogenated Nitrile Butadiene Rubber (HNBR).

Read MoreThis gallery shows off some of our overmolded gaskets molded with Ethylene Propylene (EPDM).

Read MoreOvermolding is a specialized process. Here’s how we make overmolded gaskets and seals at our plant in Tijuana, Mexico.

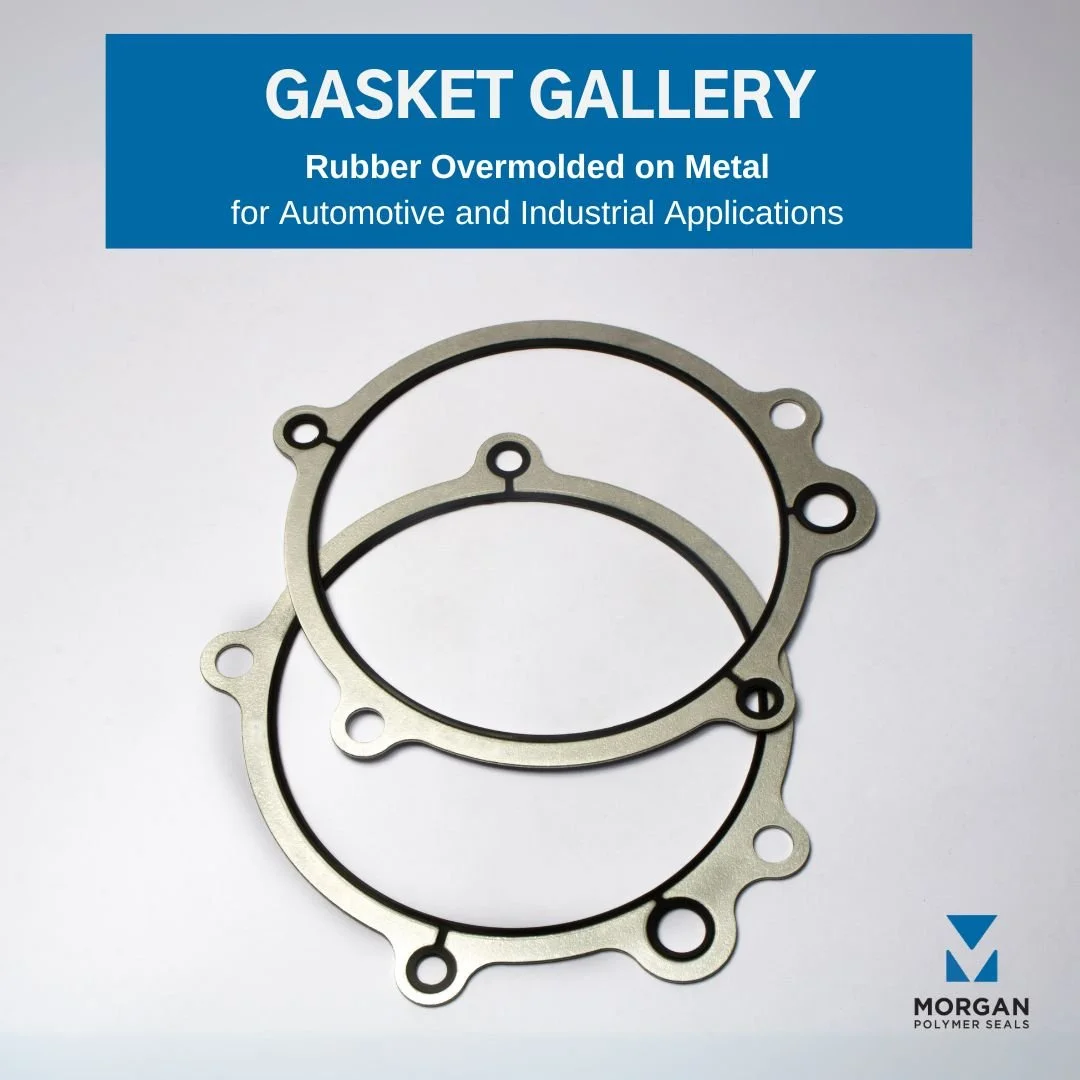

Read MoreThis gallery shows off some of our overmolded gaskets molded with a combination of metal and rubber, including silicone, HNBR, FKM, and Vamac

Read MoreThis gallery is features (even more) seals made with self-lubricating high-consistency rubber silicone (HCR).

Read MoreSelf-lubricating (or Self-Bleeding or Oil-Impregnated) silicones are very helpful for seals that require reduced friction for various reasons.

Read MoreElringKlinger has awarded Morgan Polymer Seals “supplier of the year” for components in 2023.

Read MoreWhat is “takeover tooling”, and could your supply chain benefit from it?

Read More