"Self-Lube" Silicone: When Does It Matter?

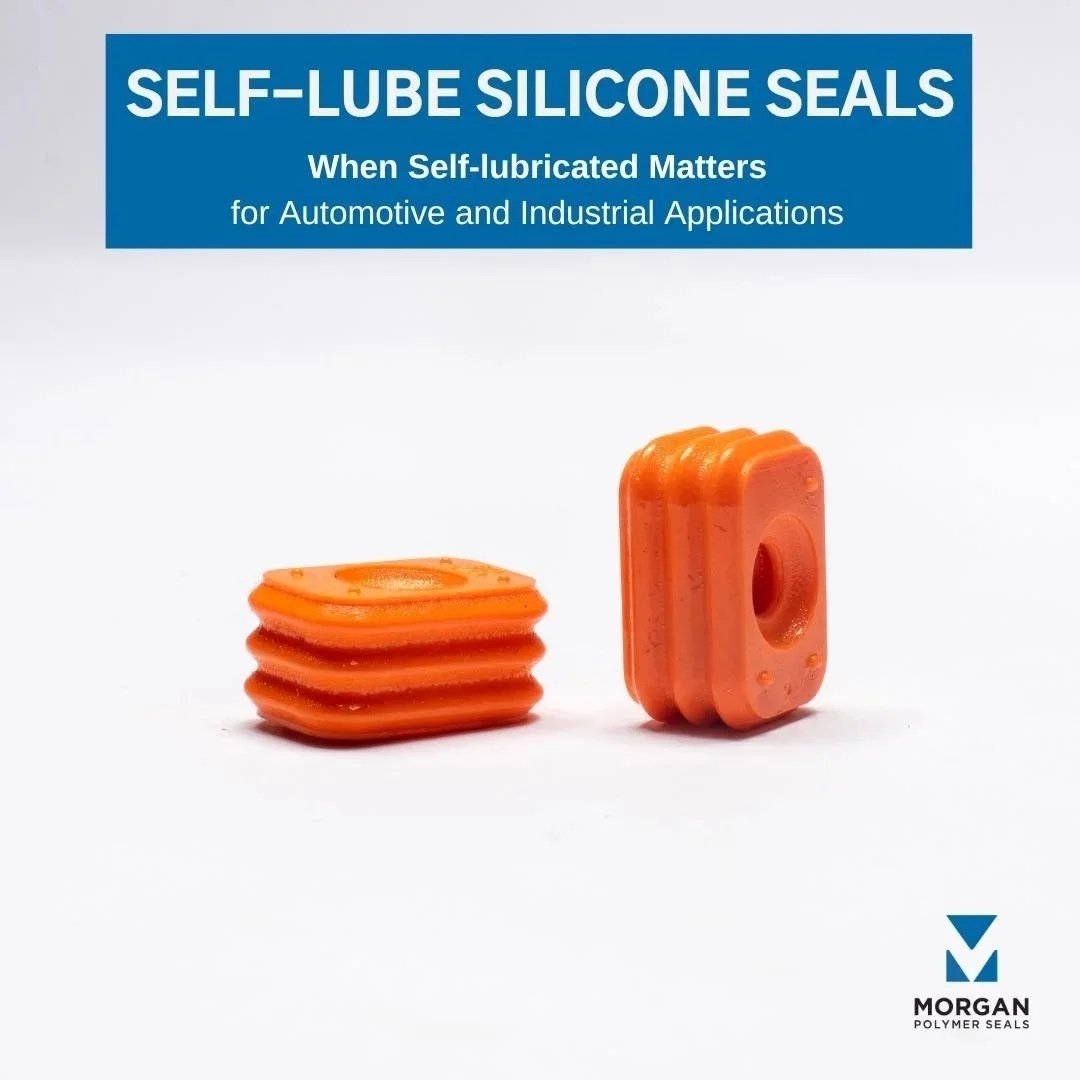

Photo: Self-Lube HCR Silicone Ethernet Connector Seals orange

Self-Lubricating Silicone Seals for Automotive Assembly Efficiency

In automotive manufacturing, small inefficiencies multiply quickly. A few extra pounds of insertion force or a minor seal nick during installation can create scrap, slow line speeds, and warranty risk.

Self-lubricating (oil-impregnated or self-bleeding) silicone seals are engineered to reduce friction at the material level — eliminating the need for a secondary lubrication process while improving installation consistency.

Why Automotive Programs Use Self-Lube Materials

These compounds are commonly specified when:

Seals are hand-installed and insertion force must remain controlled (peripheral seals)

Tight tolerances increase installation risk (e.g., MAT seals)

Automated assembly requires repeatable insertion performance

Corrosion protection at the interface adds value

Lower friction reduces:

Installation damage

Line variability

Rework and scrap

Operator strain

For Tier suppliers and OEM assembly plants, that translates directly to throughput and quality gains.

Eliminating a Process Step Improves Quality and Cost

Traditional surface lubrication introduces variability — coverage can be inconsistent, wear off during handling, or require additional labor and equipment.

With self-lubricating silicone:

Lubrication migrates evenly to all surfaces

Internal geometries receive the same benefit as external faces

Lubrication is continuously replenished over time

A secondary process step is eliminated

While the compound carries a modest material premium, removing a lubrication operation often lowers total system cost — especially in high-volume automotive programs.

Why Silicone Is the Preferred Platform

Both HCR (High Consistency Rubber) and LSR (Liquid Silicone Rubber) are well-suited for self-lubricating formulations.

VMQ silicone naturally allows controlled oil migration to the surface without significant performance loss when oil content is properly engineered (typically ≤8%). This balance makes silicone more stable than alternative elastomers that may experience greater property degradation, temperature limitations, or compatibility concerns when blended with lubricants.

For under-hood and high-performance environments, that stability matters.

Designed for Production Realities

Self-lubricating compounds are not off-the-shelf solutions. Oil type, loading percentage, and migration rate must be engineered to meet compression set, tensile, and environmental requirements.

If your automotive program is experiencing insertion variability, installation damage, or looking to simplify the assembly process, a self-lubricating silicone seal may offer measurable improvements in both quality and cost.

Scroll to browse our product photos and click “contact us” to reach a product specialist who can quote your next program.

Do you need a program quoted? Click below and a product specialist will get back to you right away.

To learn more about choosing HCR vs LSR we have several articles on the subject.