What is Takeover Tooling? (And is it risky?)

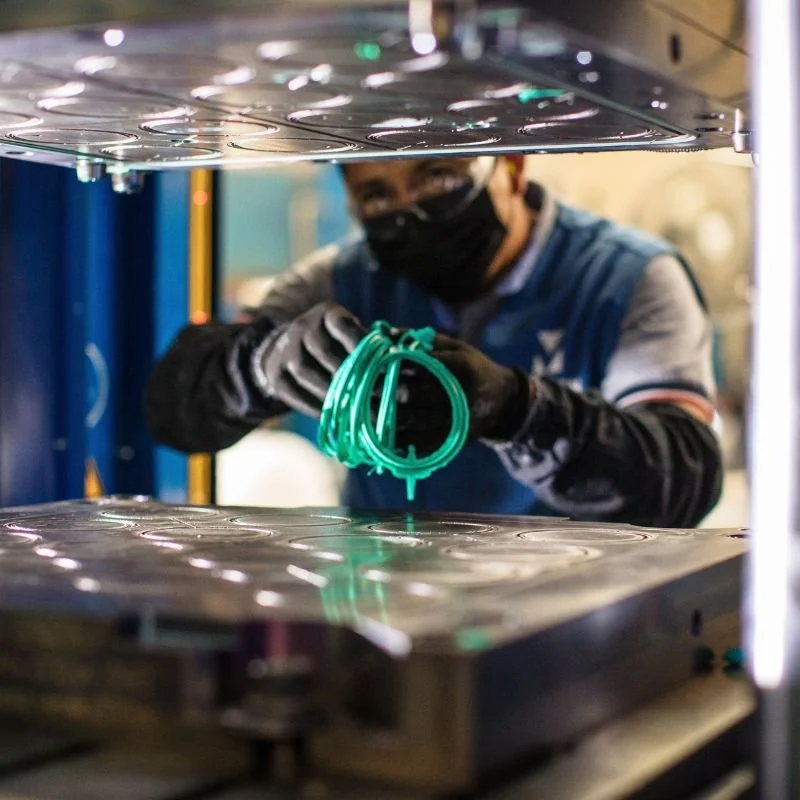

Photo: a rubber injection tool opening at our plant in Tijuana, Mexico

What is Takeover Tooling?

In the world of rubber gasket molding, "takeover tooling" happens when a manufacturer or OEM (Original Equipment Manufacturer) decides to switch suppliers but keeps using the same mold, or tool, they were using with the old supplier. Sometimes, you'll hear this called “customer-owned tooling” because the OEM owns the mold, not the supplier.

So, why would a company do this? Usually, it's because they’re having trouble with their current supplier—maybe there are quality issues, delivery delays, or, increasingly, because their supplier raised prices. By moving the mold to a new supplier, the OEM avoids the cost of creating a whole new tool. Handy, right?

A press operator at his injection station with closed tool

What are the risks of Takeover Tooling?

Takeover tooling isn’t without its risks for both the manufacturer and the new supplier. For the new supplier, there’s the chance that the mold they receive is damaged or just doesn’t work well with their machines. This can lead to unexpected expenses and slow down production. In some cases, the mold might not even be compatible, and a replacement could be needed after all.

Another tricky part is material. Since each supplier may use slightly different materials, the switch can cause changes in the part’s dimensions or functionality.

For the OEM, there’s also the challenge of making sure they have enough parts stocked up to cover any downtime during the transition. They’re putting a lot of trust in the new supplier, and if things go wrong, they may have to return to the old supplier—often at a higher cost.

What are the benefits of Takeover Tooling?

Press operator removes parts from a rubber injection tool

When takeover tooling works out, the biggest win is usually cost savings. The OEM can change suppliers without paying for a new tool, which can save a lot of money. It also saves time, as they skip the waiting period required to build a new tool from scratch.

The new supplier can usually speed up the PPAP (Production Part Approval Process) too, since they’re working with a tool that already has a proven record.

How can an OEM make takeover tooling a success?

At Morgan Polymer Seals, we’ve managed successful takeover tooling projects for OEMs looking to switch from suppliers who just weren’t cutting it anymore.

Sean Morgan and Thomas Morgan with Maplan press and closed tool

The process kicks off with a market test RFQ (Request for Quote) to confirm that switching suppliers will bring a cost benefit. It’s also a good time for the OEM to think about what impact this change could have on their relationship with their current supplier.

From there, our engineering team reviews a drawing of the tool and works closely with the customer to make sure the mold is in the right shape to run on our equipment. Good communication and cooperation at this stage help set everyone up for a smooth transition.

Once we get the mold from the OEM’s previous supplier, we make sample parts to check that everything measures up, then PPAP the program to ensure compatibility with our production lines.

Do you think takeover tooling might help your business? Contact us to learn more.

This article has been edited from it’s original publication on Nov 3, 2022.