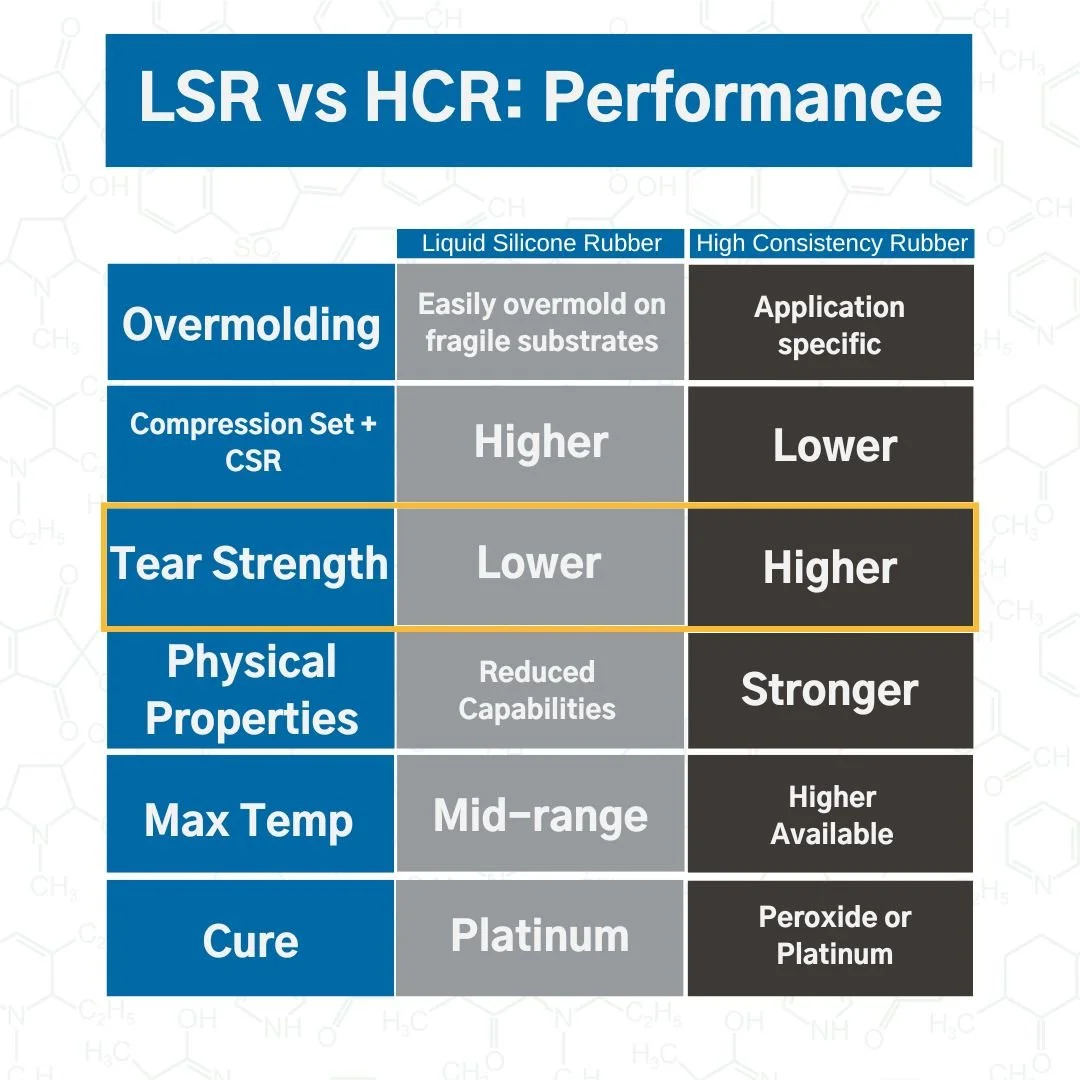

LSR vs. HCR: Tear Strength

Cushion Seal molded in Mexico with HCR Silicone

How does the tear strength performance of LSR compare to an HCR silicone? First let’s take a look at what ‘tear strength’ is in the context of automotive gaskets, and why it matters.

Tear strength is a measure of a material's resistance to tearing. It quantifies the force required to propagate a tear through a material once an initial cut or nick has been made. In the context of polymer gaskets and seals, especially for automotive applications, tear strength is critical because it indicates how well the material can withstand mechanical stresses without tearing apart.

1. Durability and Longevity:

Mechanical Stresses: Automotive gaskets and seals are subjected to various mechanical stresses during installation and operation. High tear strength ensures that these components do not easily rip or tear when being fitted or under pressure.

Longevity: Materials with higher tear strength tend to last longer in service, reducing the frequency of replacements and maintenance.

2. Performance under Vibration:

Vibration Resistance: Automobiles experience constant vibrations from the engine and road conditions. Gaskets and seals with high tear strength are better equipped to withstand these vibrations without failing.

3. Pressure Resistance:

Sealing Integrity: Many automotive seals and gaskets need to maintain their integrity under varying pressure conditions. High tear strength helps prevent the material from tearing under pressure, ensuring a consistent seal.

4. Environmental Factors:

Temperature and Chemical Resistance: While tear strength itself is a mechanical property, materials with high tear strength often also possess good resistance to temperature fluctuations and exposure to automotive fluids and chemicals.

So now that we understand the importance of a gasket’s tear strength, how does a gasket molded with LSR compare to a gasket molded with an HCR Silicone or other High Consistency Rubber?

Automotive gasket molded in Mexico with Blue LSR

Liquid Silicone Rubber (LSR)

Moderate Tear Strength: LSR generally exhibits moderate tear strength. This level of tear resistance is sufficient for many gasket applications, where the gasket must maintain its integrity and provide a reliable seal without being subjected to extreme mechanical stress.

Consistency and Uniformity: The injection molding process used with LSR ensures that the tear strength is consistent and uniform across all produced gaskets. This uniformity is crucial in automotive gasket manufacturing, where consistent performance and reliability are key.

Application Suitability: The moderate tear strength of LSR is adequate for automotive gaskets that are not exposed to high mechanical stress but require excellent sealing properties, flexibility, and precision.

Seal Flange molded in Mexico with Green LSR

High Consistency Rubber (HCR)

Higher Tear Strength: HCR silicone generally has a higher tear strength compared to LSR silicone. This makes HCR silicone more resistant to tearing, which is beneficial for gaskets that might experience more significant mechanical stress or abrasion during installation and use.

Durability Under Stress: The higher tear strength of HCR silicone makes it suitable for gaskets in applications where parts are exposed to substantial mechanical stress or need to endure harsher conditions.

Varied Performance: Depending on the specific formulation and processing, HCR silicone can be optimized for even higher tear strength, offering greater durability for demanding gasket applications.

Perimeter Seal molded in Mexico with Orange HCR Silicone

While LSR offers moderate tear strength suitable for many automotive gasket applications requiring precision, flexibility, and environmental resistance, HCR silicone stands out with its higher tear strength, making it more appropriate for gaskets subjected to significant mechanical stress and harsh conditions. For instance, LSR may not be the ideal choice for molding mat seals, but it is not necessarily ruled out for such gaskets.

The choice between LSR and HCR silicone for automotive gasket manufacturing will depend on the specific requirements, such as the need for intricate design and environmental resilience (favoring LSR) versus the need for high mechanical durability and tear resistance (favoring HCR).

Do you have a program you’d like us to quote? Click the button below and we’ll be happy to help.

Chart: LSR has lower tear strength than HCR Silicone