Costs Considerations of LSR vs HCR: Cycle Time

Automotive Flange Seals molded in Mexico with Green LSR (liquid silicone rubber)

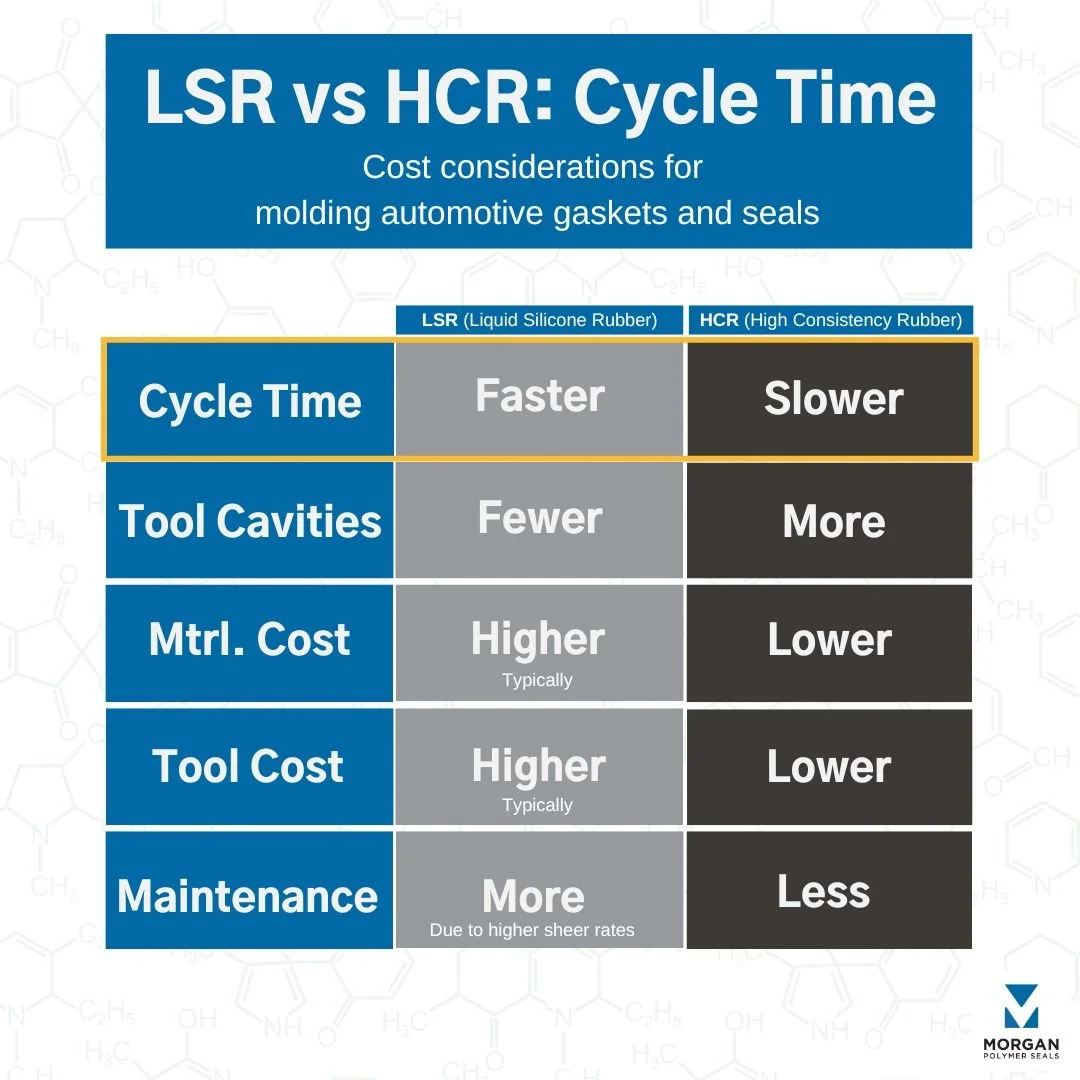

As part of our ongoing series of articles about molding automotive gaskets with Liquid Silicone Rubber (LSR) versus molding with High Consistency Rubber (HCR), this article will explore the difference in cycle times between the two materials. Liquid Silicone Rubber generally has faster cycle times in molding processes than High-Consistency Rubber - primarily because of the differences in their material properties and the molding techniques used.

Here's why LSR typically has faster cycle times:

1. Injection molding process: LSR is typically processed using liquid injection molding (LIM) techniques, where the material is injected into a mold cavity under high pressure. This process allows for rapid filling of the mold cavities, leading to shorter cycle times compared to compression molding or transfer molding techniques often used for HCR.

2. Fast curing: LSR cures rapidly at elevated temperatures, often within a few minutes, depending on the thickness of the part and the specific formulation of the material. This fast curing time enables quicker demolding of parts and reduces overall cycle times. (Continued below)

Chart: Cycle Time for an LSR molding process is typically faster than for an HCR material with compression molding

3. Minimal post-curing required: While some post-curing may be necessary for LSR parts to achieve optimal properties, it is typically shorter compared to the post-curing requirements of HCR materials, which may need longer oven curing times to achieve full cure and desired properties.

4. High productivity: The combination of rapid injection molding and fast curing makes LSR a highly productive process, especially for high-volume production runs.

In contrast, HCR materials are typically processed using compression molding techniques, which may involve longer cycle times due to factors such as preheating of the material, longer molding and curing times, and potentially longer post-curing requirements.

Ring seals for automotive manufactured in Mexico, made from Green HCR Silicone

Overall, the faster cycle times of LSR make it a preferred choice for applications where rapid production and high efficiency are essential, such as in many automotive and industrial applications. Compared to HCR, LSR is fast to inject and fast to cure, which saves time, labor, and electricity. And these savings can often overcome some of the costlier elements of LSR molding - which we’ll discuss in our next article.

Click for more about LSR vs HCR.

HCR Silicone Gasket for Industrial application, made in Mexico

Here’s a quick video that shows our LIM presses adding LSR material to complete an overmolded gasket in Mexico.

Do you have a program you’d like us to help with? Click the contact button below and we’ll reply right away.