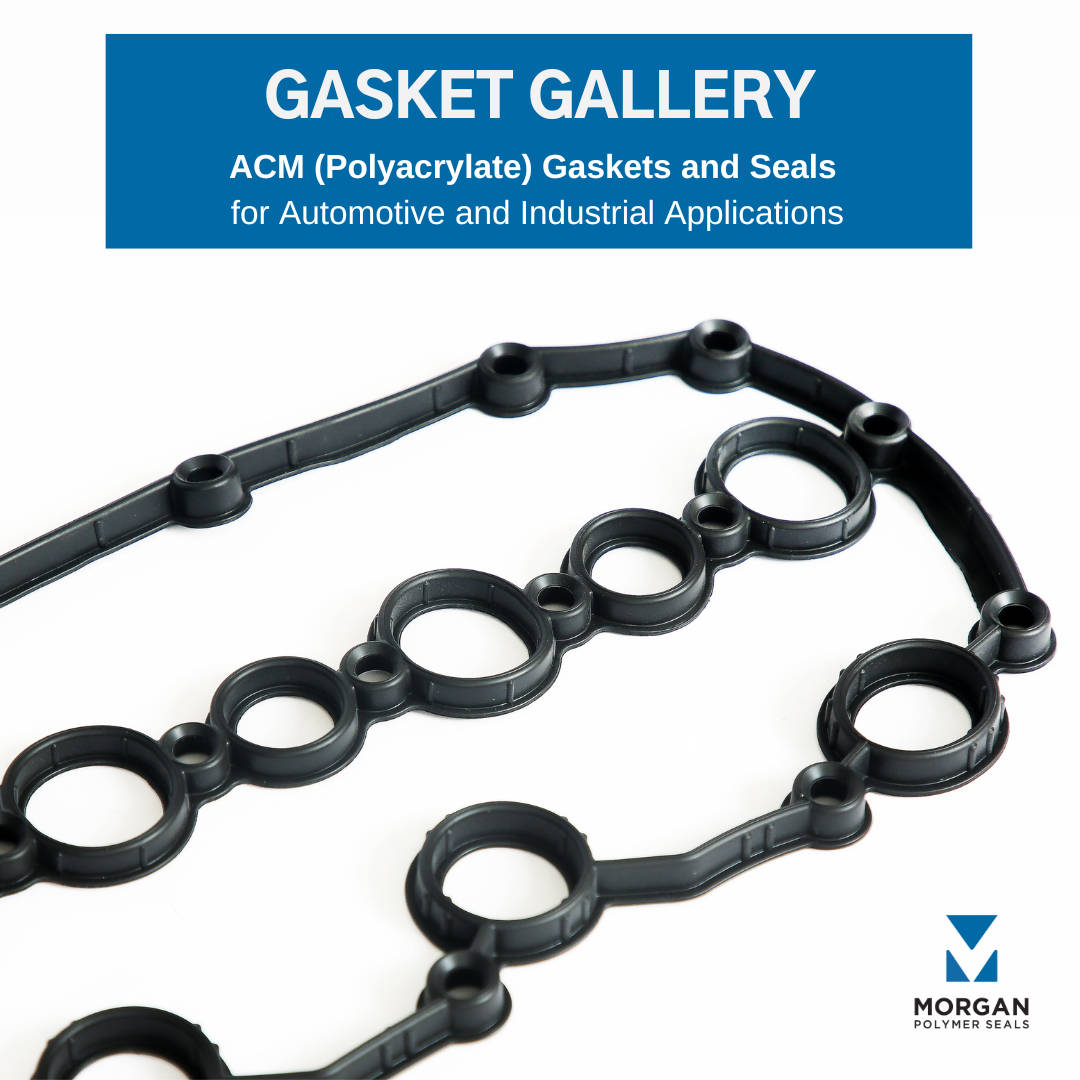

Gasket Gallery: ACM Seals (Polyacrylate)

Polyacrylate rubber (ACM) is a synthetic elastomer known for its superior resistance to oils, high temperatures, and oxidation. We typically use ACM for oil seal applications and engine sealing applications, including press-in-place (PIP) gaskets and carrier gaskets in powertrain systems.

This article includes a gallery of some of the ACM seals we manufacture in Mexico, followed by an explanation of key capabilities that help explain why we use ACM for critical automotive applications.

Capabilities of Polyacrylate in Molding Gaskets

1. Precision Molding: Polyacrylate can be molded with high precision, enabling the production of gaskets with intricate designs and tight tolerances. This precision is critical for ensuring a proper fit and effective sealing in complex assemblies, such as those found in automotive engines and industrial machinery.

2. Versatility in Compounding: Polyacrylate rubber can be compounded with various additives to enhance specific properties such as hardness, abrasion resistance, and heat resistance. This versatility allows manufacturers to tailor the material to meet the exact requirements of different gasket applications.

3. Consistency and Reliability: Polyacrylate offers consistent performance across different production batches, which is crucial for maintaining quality and reliability in gasket manufacturing. This consistency ensures that gaskets made from polyacrylate perform predictably and meet stringent industry standards.

4. Cost-Effectiveness: Compared to some other high-performance elastomers, polyacrylate is relatively cost-effective. This cost advantage, combined with its robust performance characteristics, makes it an attractive material for large-scale gasket production in both the automotive and industrial sectors.

5. Compatibility with Various Processing Methods: Polyacrylate can be processed using various molding techniques, including compression molding, injection molding, and transfer molding. This compatibility with different processing methods allows for efficient and cost-effective production of gaskets in various shapes and sizes.

To learn more about ACM, and other materials we use for molding automotive gaskets, visit our products page.

Do you have a gasket you’d like us to quote? Click the ‘contact us’ button and we’ll get back to you right away.

Strip of raw Polyacrylate (ACM)