Electrical Connectors for Automotive Manufacturing

Silicone electrical connector seals are an essential component of wire harness assemblies for a variety of applications, including automotive, heavy-duty trucks, aerospace, and telecommunications. The seal provides two vital functions, including a secure electrical connection and a moisture barrier to ensure continuity of the circuit. In this article, we will examine the manufacturing process of silicone electrical connectors and their application in the automotive industry.

Manufacturing Process

The life cycle for silicone electrical connectors involves several stages. The first stage is the design and development of the product. This involves creating a 3D model of the product and if required, Finite Element Analysis (FEA), which is used to simulate how the connector and seal work function in application. Once the analysis of the system is complete, the 3D model is used to produce the mold for prototype and ultimately, production tooling.

Ahead of producing the mold, the proper material is selected for the application and product. Typically we are molding electrical connector seals with either a two-part material known as Liquid Silicone Rubber (LSR) or Heat Cured Rubber (HCR) silicone. The material is injected into the mold under pressure and is cured in the tool using the heat of the mold plates (platens) to cross-link the rubber to create the finished component.

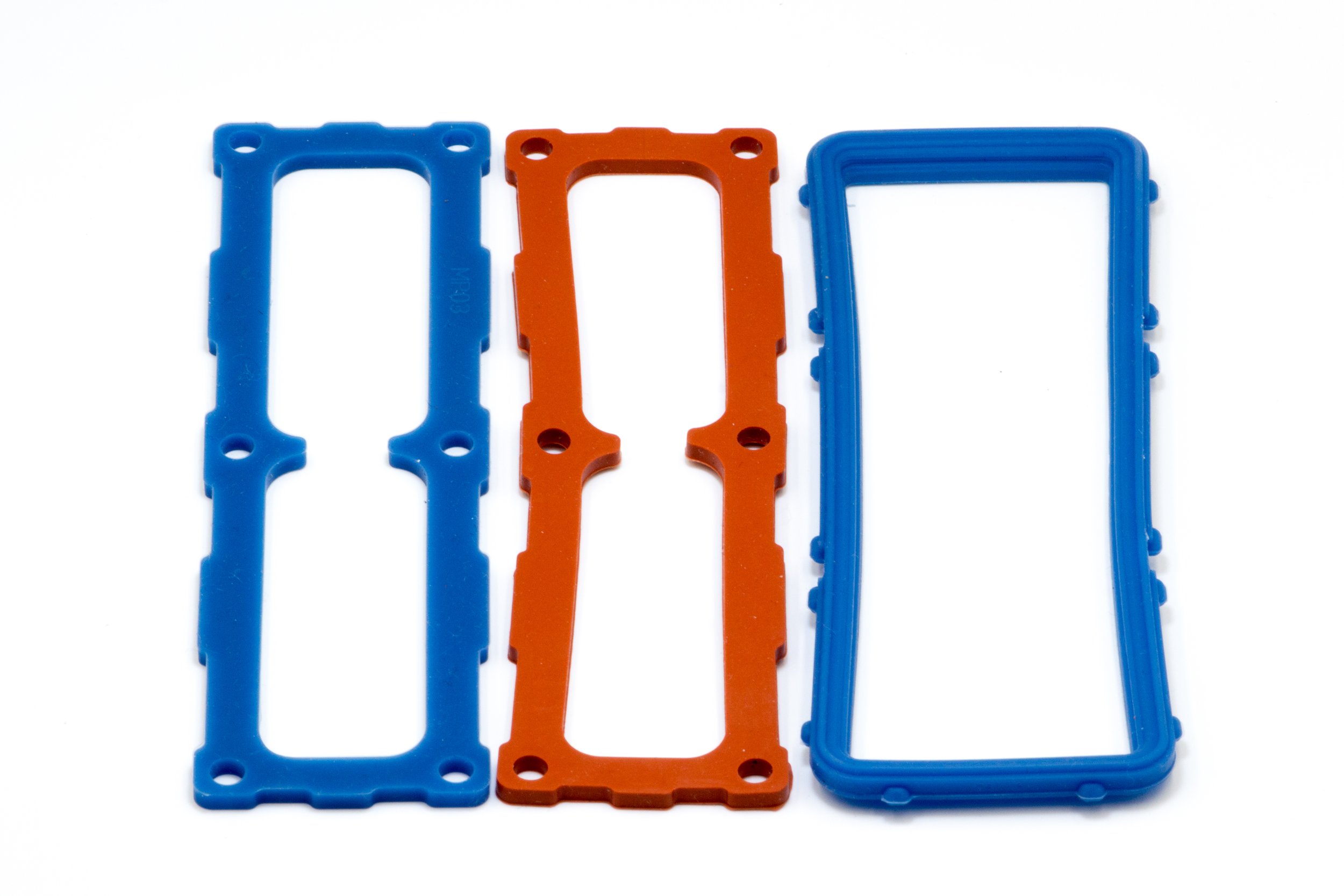

After the silicone material has cured, the connector is removed from the mold and inspected for defects using our rigid quality standards. We utilize a combination of manual and automated vision inspection to qualify that the parts meet our customers’ expectations for fit, form, and function. Ultimately, it is the print specification that dictates the quality standards that the connector seal must meet.

Liquid Silicone Rubber molding in Mexico

Types of Silicone Electrical Connectors

1. Plug Connectors: Plug connectors are used to connect two or more electrical components together. Silicone plug connectors are ideal for use in extreme temperature environments, as they can withstand temperatures of -60°C to 230°C.

2. Socket Connectors: Socket connectors are used to receive plug connectors and create a secure electrical connection.

3. Terminal Connectors: Terminal connectors are used to connect electrical wires to other components in a circuit.

4. Cable Grommets: Cable grommets are used to protect electrical cables from environmental factors such as moisture, dust, and vibration.

Conclusion

At Morgan Polymer Seals and our sister company Premium Seals, we have decades of experience manufacturing electrical connectors for automotive, industrial, aerospace, and telecommunication applications. Do you have a program that you’d like us to quote? Click below and a product specialist will reply immediately.